LaceLok® Resources

Installation Practices

LaceLok offers multiple installation configurations making it suitable for a variety of applications. It is exceptionally strong with a single wrap, additional strength can be achieved by simply applying a second or third wrap around the wire harness prior to activation. Multiple wrap installations should be used where increased tensile strength or additional resistance to radial motion is needed. Double and triple-wrap configurations are ideal for pressure-sensitive components such as coaxial and fiber optic cables.

| Number of Wraps | Application | Minimum Tensile Strength |

|---|---|---|

| Single | 1/4" to 1" (.6 cm to 2.5 cm) diameter cable bundles | 55 lbs. (240 N) |

| Double | <1/4" and 1" to 3" (< .6 cm to 2.5 cm to 7.5 cm) diameter cable bundles | 110 lbs. (490 N) |

| Triple | 3" (> 7.5 cm) diameter cable bundles or exposure to JP-8 jet fuel | 165 lbs. (730 N) |

For more application and installation information view the LaceLok datasheet:

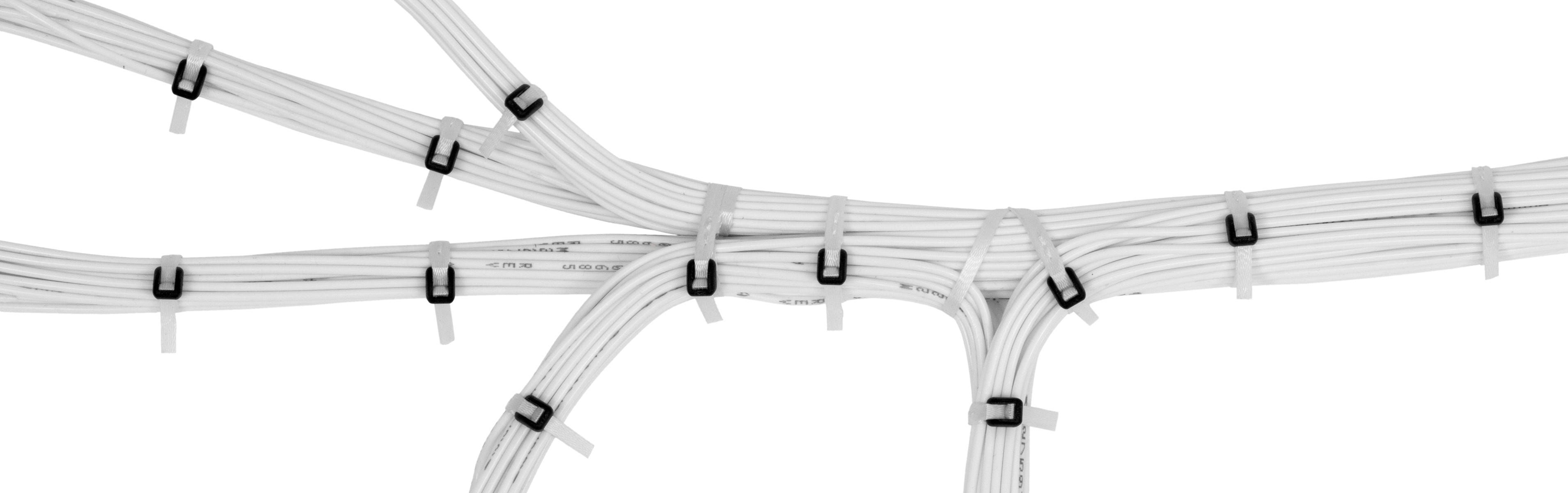

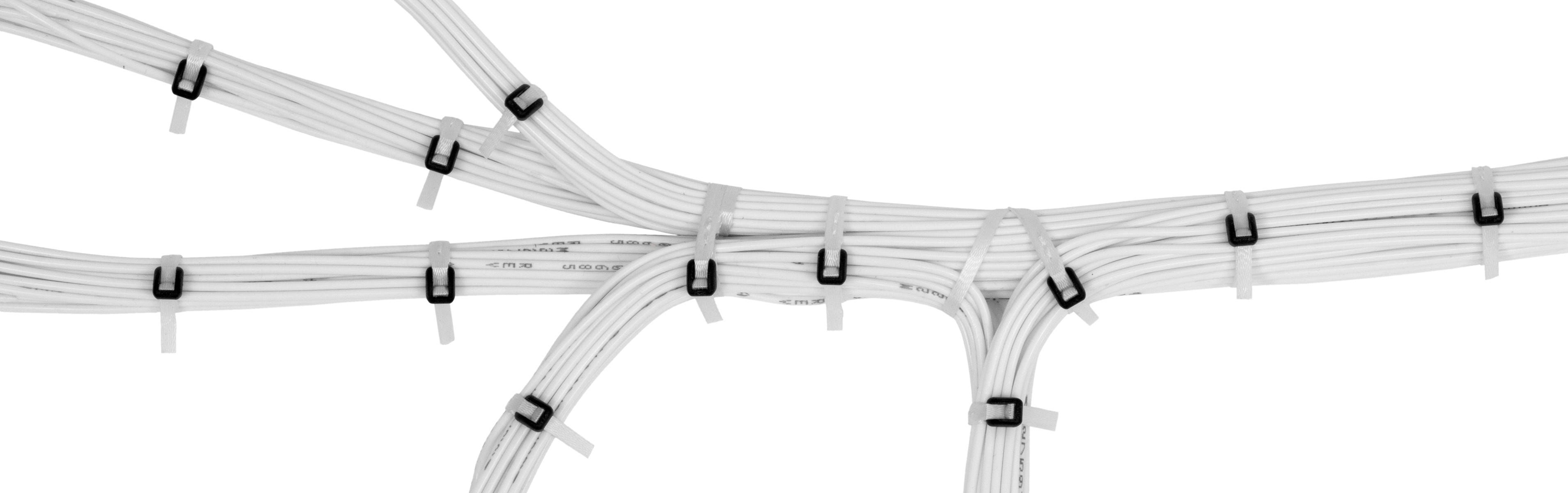

Breakouts

LaceLok can be used to create breakouts in a similar application method as plastic cable ties or hand-tied lace. Examples of breakouts include, but are not limited to, the following examples. It is up to the responsible engineering authority to determine the applicable method and application of LaceLok.

Lockstitch

A lockstitch method can be used for larger bundles, bundles of multi-conductor cables, or bundles where additional resistance to lateral movement is needed. A lockstitch is completed by looping the lace around one component and then completing the wraps and termination as normal.

For more application and installation information view additional resources below:

Materials

LaceLok is comprised of three components: the lacing tape, the fastener, and the thread. All components are made of materials that are resistant to chemicals and can withstand an extreme temperature range.

The lacing tape used in LaceLok is constructed of the same material as typical hand-tied lace, meta-aramid fiber A-A-52084 finish C. This material offers excellent heat and flame resistance, outstanding strength, and is non-conductive. Finish C lace features a synthetic rubber elastomer coating which improves its ability to maintain tension when locked and terminated in the fastener.

The fastener is made of engineered thermoplastic PEEK (polyetheretherketone) material, which is ideal for aerospace applications. It offers a very high strength-to-weight ratio while maintaining resistance to heat, flame, and chemicals including JP-8 jet fuel, hydraulic fluids, lubricating oil, and isopropyl alcohol.

The thread is manufactured to MIL-C-572 Type PAA Form Y. It is intended to secure the fastener onto the lace until it is terminated on a bundle. The thread plays no role in the security of LaceLok once the fastener is terminated.

Packaging

LaceLok is sold in packages of 100 and is available in multiple colors and lengths.